You’ve reached your limit!

To continue enjoying Utility Week Innovate, brought to you in association with Utility Week Live or gain unlimited Utility Week site access choose the option that applies to you below:

Register to access Utility Week Innovate

- Get the latest insight on frontline business challenges

- Receive specialist sector newsletters to keep you informed

- Access our Utility Week Innovate content for free

- Join us in bringing collaborative innovation to life at Utility Week Live

A major collaborative project led by Thames Water is striving to slash energy consumption in wastewater treatment through the pioneering application of cold anaerobic processes.

In September, a Thames Water-led collaboration – comprising the University of South Wales, Welsh Water, South West Water, United Utilities, Scottish Water, Yorkshire Water and Northumbrian Water – netted more than £6 million from Ofwat’s first Water Breakthrough Challenge to collaboratively test two cold anaerobic wastewater treatment processes in a bid to decarbonise wastewater treatment and boost resource recovery.

According to Thames Water statistics, the water industry currently consumes between two and three per cent of the electricity produced in the UK – the same as around two million households – with roughly 55% of the energy consumed by a typical sewage works used to process wastewater.

While anaerobic digestion is heralded as a low cost waste and wastewater treatment method, it’s usually conducted at temperatures between 20 to 45oC to support bacteria which thrive in moderate temperatures. Functioning in this range requires energy to heat, meaning that cold processes potentially offer both cost and environmentally friendly alternatives.

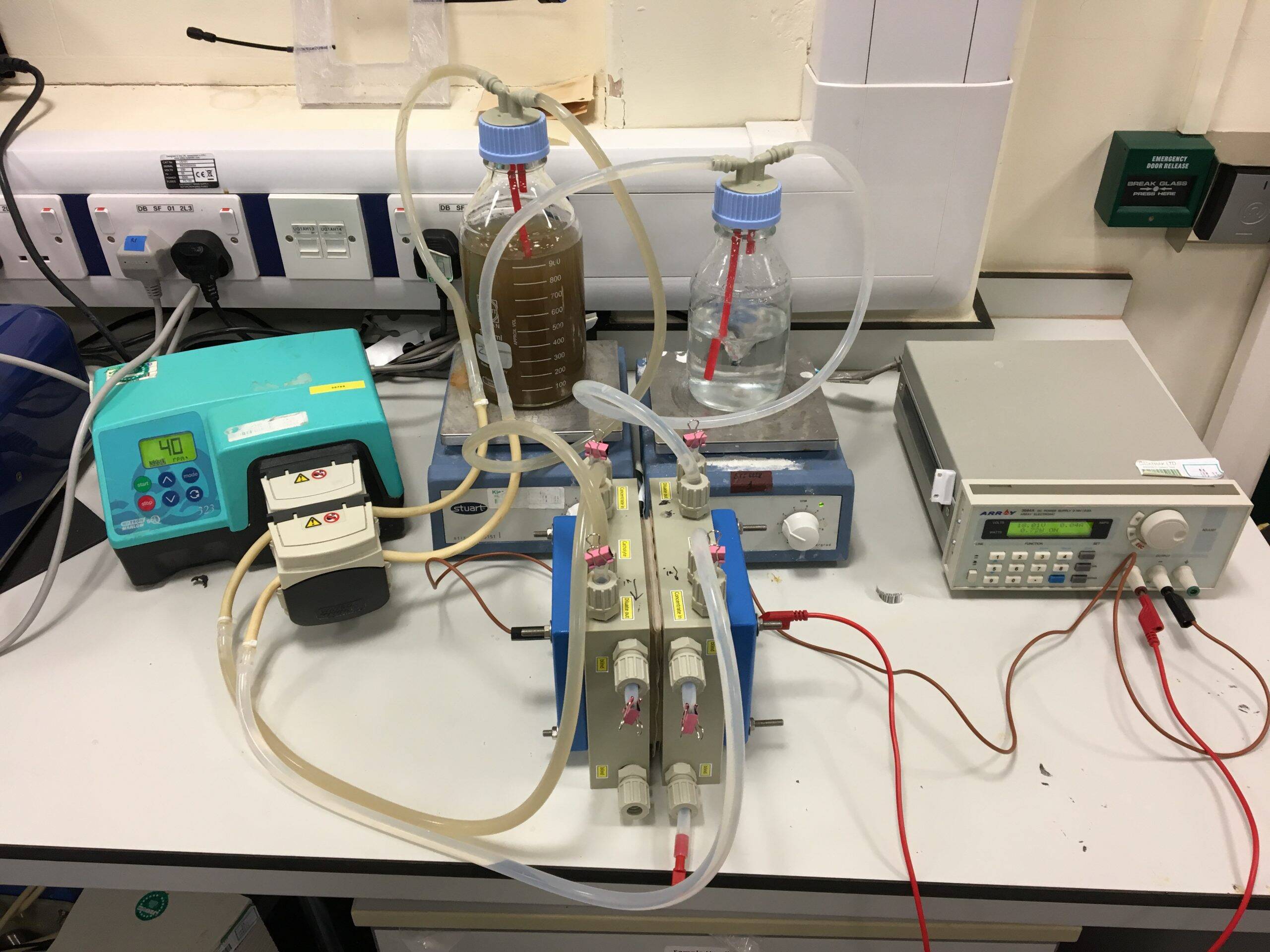

As such, the seven-strong consortium will test a membrane-free cold process which maximises biogas generation, removes nitrogen and phosphorus, and will be deployed as a mobile unit at multiple sewage treatment works to test different wastewater concentrations. This will then inform its deployment at a larger demonstration plant.

The second process treats crude sewage at a larger scale by combining existing technology with alternative nutrient removal apparatus at laboratory-scale. Micropollutant removal and pathogen antimicrobial resistance will also be tested at all trials.

Leaving a legacy

Thames, which serves 15 million customers across London and the Thames Valley, believes that such cold processes have the potential to transform wastewater treatment by eliminating energy usage from conventional methods, reducing nitrous oxide emissions and thereby the sector’s carbon output, as well as yielding phosphorus and nitrogen in forms that can be readily recovered.

“I’m passionate about leaving a legacy for future generations, just like the Victorians did for us,” Sarah Bentley, Thames Water CEO, said. “I’m delighted that we’ve won this award, which will allow us to change our approach to the wastewater treatment process in a way that will reduce our carbon footprint.

“It’s fantastic to be able to work alongside seven great organisations who share our drive to innovate and shape the future.”

Prof Sandra Esteves, project lead at the University of South Wales, added: “The funding will enable the team to drive the novel concept integration and evaluate its impact in reducing society’s wastewater treatment energy footprint and in promoting sustainable resource recovery.”

Adapting to ambient temperatures

Andrea Gysin, Thames’ head of innovation partnerships, dived deeper into the cold anaerobic processes at the heart of the award-winning collaboration.

“Conventional wastewater treatment processes rely on bacteria to break down organic material in the presence of oxygen, which causes carbon dioxide and nitrous oxide to be emitted to atmosphere,” she explained.

“In the absence of air or oxygen – anaerobic conditions – different types of bacteria will thrive. When these bacteria break down organic material, they produce a mixture of gases which is rich in methane that can be used in place of fossil fuels.”

Gysin continued that while the bacteria involved in the two cold processes to be tested are similar to those found in the anaerobic procedures currently used to treat sludge, the wastewater involved is far more dilute and lower in temperature. “Anaerobic digesters are heated to around 37°C – this wouldn’t be feasible for the huge volumes of wastewater we treat,” she added.

“Cold anaerobic treatment has been successfully applied in warmer climates – our challenge is to create the conditions in which the bacteria can treat wastewater at the ambient temperatures experienced year-round throughout the UK,” she continued.

Enabling rapid adoption

Despite challenges posed by a milder climate, Gysin believes cold anaerobic processes could “completely transform” the water industry’s wastewater treatment operations.

“Not only will it reduce the amount of energy consumed and the direct emissions produced, but it will also reduce sludge production,” she explains.

“Reducing sludge production may seem counter intuitive as we generate energy from sludge, however, we would be reducing the production of the surplus activated or secondary sludge, which is typically harder to digest and therefore yields less energy than primary sludge.

“We anticipate that we would continue to anaerobically digest primary sludge at our larger sites, generating energy in the form of biogas,” Gysin continued. “Sludge from smaller sites is typically transported to a local sludge treatment center by road tanker. At small sites we are seeking to eliminate up to 96% of the sludge production to avoid transporting it by road, thereby further reducing carbon emissions, costs and vehicle movements.”

She adds that the input of project partners from University of South Wales, Welsh Water, South West Water, United Utilities, Scottish Water, Yorkshire Water and Northumbrian Water will be “crucial” in ensuring that the project develops a robust and widely applicable solution.

“We believe our partnership with six other water companies and the University of South Wales is ideally placed to do this and to enable the rapid adoption of cold anaerobic digestion once it is proven,” Gysin said. “Additionally, we will create an opportunity for water companies to play an important role in the circular economy by recovering nutrients – nitrogen and phosphorus – that could be used in a range of applications from fertilisers to energy production.

“In that respect, this project is just the beginning,” she added. “We recognise that a successful circular economy model will require wider collaboration with additional stakeholder groups. We believe the open innovation model that we are adopting throughout will continue to enable innovation beyond the project.”

Understanding process performance

With regards to next steps, Gysin explained that the consortium is poised to roll out its mobile pilot plant to test a novel technology configuration for cold anaerobic wastewater treatment.

“The mobile pilot will be operated at a number of sites – across multiple partners – to understand how the process performs with different wastewater characteristics,” she said.

“We will then build a commercial scale demonstration plant at a Thames Water site to prove the technology configuration at scale and de-risk the subsequent roll-out.

“In parallel with this, Dŵr Cymru Welsh Water will be adapting their existing anaerobic demonstration plant at Builth Wells to treat crude sewage – rather than settled sewage – making the solution more beneficial for smaller sites.”

See this content brought to life at Utility Week Live, 17-18 May 2022 NEC Birmingham

New approaches to wastewater treatment and resource recovery is one of the frontline challenges at the heart of Utility Week Live 2022’s live content programme.

View the challenges and be alerted for tickets to the industry’s most eagerly awaited reunion at utilityweeklive.co.uk.

Please login or Register to leave a comment.