You’ve reached your limit!

To continue enjoying Utility Week Innovate, brought to you in association with Utility Week Live or gain unlimited Utility Week site access choose the option that applies to you below:

Register to access Utility Week Innovate

- Get the latest insight on frontline business challenges

- Receive specialist sector newsletters to keep you informed

- Access our Utility Week Innovate content for free

- Join us in bringing collaborative innovation to life at Utility Week Live

Ahead of WWT’s Smart Water Conference 2022, Utility Week Innovate dives into how UK water companies are deploying both old and new technology to tackle leakage.

According to figures from Water UK, there are almost half a million kilometres of underground water pipes covering the UK. As such, when leaks inevitably occur, pinpointing and fixing them without causing major disruption can be a major challenge.

Yet further figures from the trade association show that the industry has reduced leakage levels by a third since the 1990s, harnessing a range of new technology and innovation, with water companies in England recently committing to cut leakage by a further 16% by 2025.

This reduction will be enabled by new resources and techniques such as satellite imaging, thermal imaging drones, acoustic equipment and even sniffer dogs to find and fix leaks – areas in which widespread innovation is already taking place.

Ahead of WWT’s Smart Water Conference 2022 – where industry experts will discuss smart solutions to leakage and demand management as part of a schedule packed with case studies, regulatory insights and cutting-edge technological advancements helping the industry to enhance delivery outcomes – Utility Week Innovate rounds up some of the latest examples of innovative solutions already in play.

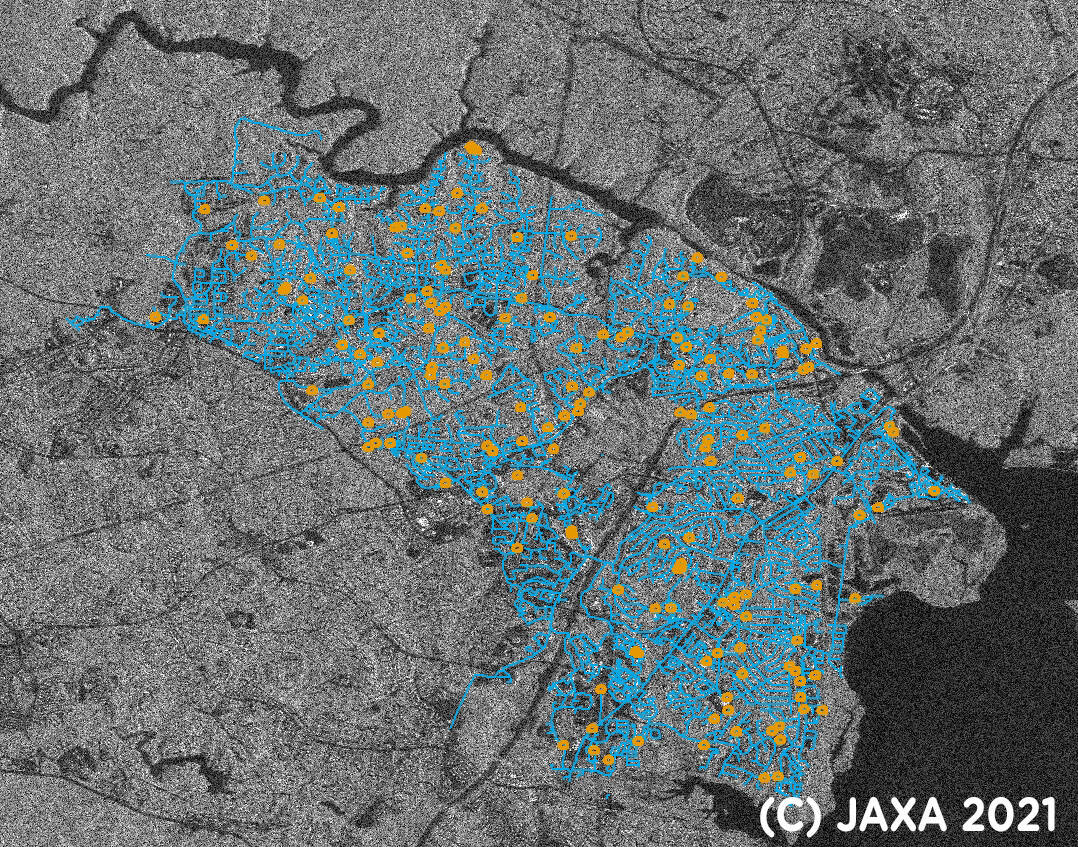

Spotting leaks from space

South West Water has teamed up with satellite data analysts Asterra – which provides data-driven solutions for water utilities and government agencies – to use satellites to find water leaks underground and cut leakage levels across its network.

Asterra’s product, Recover, helps save treated water and thereby reduce associated carbon emissions. The technology is the same as that used to search for water on other planets, and works by using microwave sensors onboard a satellite to take photos of the earth showing potential water leaks.

As microwaves can penetrate up to 2m underground, the data will highlight potential leaks, invisible above ground, so that South West Water’s leakage technicians can make necessary repairs.

As microwaves can penetrate up to 2m underground, the data will highlight potential leaks, invisible above ground, so that South West Water’s leakage technicians can make necessary repairs.

“We are continually working to improve our leakage performance and are on track to meet our leakage reduction plan, using innovative technology to identify leaks,” said Wayne Arscott, leakage delivery manager at South West Water.

“We maintain enough underground water pipes to reach Australia if laid end to end and investing in technology like this is key to helping us achieve our challenging leakage reduction targets.”

Early innovators in the use of satellite technology include Northumbrian Water, which has previously engaged industrial solutions company Suez UK and their partner for satellite leakage technology, Asterra, to combat leakage in their area.

Sniffing out remote leakages

The provider of water and wastewater services in the north west of England, United Utilities has taken a lead in training leakage dogs to sniff out chlorine traces in tap water.

Sniffer dogs support United Utilities’ leakage detection team as most leaks never show above ground and engineers have to seek them out. However, a number of traditional listening techniques are difficult to deploy in rural areas as there are very few fittings or valves for them to access pipework. Dogs, however, can cover large distances quickly and find a point of interest.

As an example, in summer 2020 one-year old springer spaniel, Kilo – full name Achelous, after the ancient Greek god of fresh water – found a hidden leak in a field in Bassenthwaite, Cumbria, that could have expelled 72,000 litres a day if left undetected.

Despite success, the firm has, however, offered its four-legged friends a digital hand by enhancing its Fido leak detection tool in October 2021 to further reduce the room for human error when locating leaks.

The AI platform and in-field device uses machine-learning to listen and interpret the unique data trail left by leaks. It then tracks them down using digital triangulation to pinpoint their exact location.

According to reports by Utility Week, the technology – developed with Cloud Correlation – uses cloud computing together with AI to make Fido accurate to within 1m. Data is fed to the cloud, eliminating the need to manually input information or for any additional equipment.

Acoustic data is collected via small sensors called Fido Bugs which record acoustic and kinetic signatures. The information is then analysed by Fido in the cloud and returns the results to an engineer’s phone.

The company trialled Fido AI in December 2020 before rolling devices out across its network. Its tests showed the Fido algorithm could filter out external sounds and noises from pumps to make it 92% accurate at detecting leaks.

“Once activated, it picks up sounds, vibrations and kinetic data and feeds them back to its fast-growing leak library for real-time analysis, to say where the leaks are, to within a distance of 1m,” Fido CEO Victoria Edwards said of the tool. “It can either be used above ground as a listening stick or, like a dog, tethered to a lead and put inside the pipe itself.”

‘UK first’ leakage tech in live water mains

Anglian Water recently trialed what it claims is a “UK first” technology to find and measure leaks in live water mains as part of a new partnership with Electro Scan.

The technology uses multi-sensor, low voltage conductivity and acoustic technology to listen for and find leaks in water pipes, as well as high-resolution closed-circuit television to navigate within the pipe to assess its condition.

According to Anglian, the sensors measure the variation of electricity passing through the pipe wall. Electricity does not pass through non-metallic pipe walls but will pass through a defect or leak. The bigger the defect, the larger the electricity flow.

The technology can detect any holes in the pipe as small as 1cm in diameter as well as estimating how much water is lost in litres per second, meaning repairs can be prioritised accordingly.

This work can be undertaken in live water mains, meaning no interruption to customer supply.

Anglian had previously blazed a trail in leakage innovation by becoming the first water company in the UK to trial thermal imaging drones to detect leaking water pipes.

Anglian had previously blazed a trail in leakage innovation by becoming the first water company in the UK to trial thermal imaging drones to detect leaking water pipes.

According to Anglian, the drone’s sensor and camera can identify differences in soil temperature which could be caused by water escaping from the pipe. These differences are then investigated further by a leakage technician on-site, rather than needing to be analysed further by office-based teams.

The firm has also previously introduced an adapted form of naval technology across its network to identify and fix leaks.

Known as advanced noise loggers, the technology listens for changes in sound underwater. Placed permanently within pipes, the loggers listen through the flow of water to find hard to pinpoint leaks.

Burst pipe portal

In December, Northumbrian Water introduced a new portal to make it easier for people to report leaks as soon as they are spotted in a bid to reduce leakage and save water across the north east.

The portal, which will help to make the area more water efficient, provides customers with a simplified user experience when reporting leaks and provides automatic email updates once a leak has been reported and repaired.

To use the portal, customers have to enter their postcode to view work underway and reported leakages in their area.

“We fix thousands of leaks a year, and our teams are very responsive when it comes to carrying out repairs,” said Jim Howey, head of water networks at Northumbrian Water. “However, we can only repair leaks that we know about, which is why we are urging our customers to use the new leakage portal and help us by reporting any leaks they spot.

“We all have a role to play when it comes to saving water, and by using the new leakage portal you are helping to reduce the demand for water in our region.”

Case study: which innovations are Affinity using to tackle leakage?

After meeting its leakage reduction target of 15% during AMP6, Affinity Water is now targeting a further 20% leakage reduction during the AMP7 cycle to 2025.

“We want to follow up our success from the 2015-2020 period in having the largest reductions in leakage of all UK companies,” a spokesperson said. “While we have driven leakage down to its lowest level we have achieved as a company, it’s not as much as we planned to deliver for our 2021 year-end target.

“With the new measures we have in place using cutting edge technology and data science, we are confident that we will meet our five-year target to 2025.”

“With the new measures we have in place using cutting edge technology and data science, we are confident that we will meet our five-year target to 2025.”

Examples of how Affinity Water achieved industry leading performance include “step testing”, which allows engineers to systematically work through districts and streets, using monitoring and isolation techniques to more effectively target areas suffering from water leaks.

The company has also implemented a situational awareness tool which has been described as a “single pane of glass” providing an instant view of incidents and access to all the information they need to plan the best response and clear visibility into all aspects of Affinity’s network in real time.

In terms of new technology to be rolled out across the current AMP cycle, Affinity has – in tandem with Anglian Water – deployed high frequency correlators to overcome the historic challenge of detecting leaks on plastic pipes and reduce the number of ‘dry holes’ that are dug to find leaks on pipes. These work when two or more sensors are placed around a suspected leak to record and transmit sound to a processing unit where mathematical algorithms determine the exact location of noises, such as a hissing from a leak, on the pipe.

What’s more, Affinity has pledged to continue investment in innovative technologies during the current AMP cycle, explore the latest in data capture and analysis, machine learning and artificial intelligence to continue to drive leakage down further.

See this content brought to life at Utility Week Live, 17-18 May 2022 NEC Birmingham

Delivering smart water networks is one of the frontline challenges at the heart of Utility Week Live 2022’s live content programme.

View the challenges and be alerted for tickets to the industry’s most eagerly awaited reunion at utilityweeklive.co.uk.

Please login or Register to leave a comment.